The Borgo Terminal Containers Company was founded in 1979 at Borgo Fornari ( in the hinterland of Genoa) in a area of about 5000 square maters. The company operated in warehouse , movement, repairing and transport of containers. From year to year, the company has modified it's sphere of activity, in according to the present- but above all probable – evolution in the Genoese shipping. In 1982 it happens a first, substantial change ;the company removes to the Erzelli hill (Monte Croce), in an area of about 10.000 square meters, and changes the official name; from now on the new name will be Nuovo Borgo Terminal Containers, simply known as "Borgo" Strives the company strive to expand, and so in 2000 it becomes larger, obtaining in concession ,within the Genoa Sampierdarena Port, a state property area of about 5000 square meters : a little but efficient aim that permits to improve customer service with the aid of a railway siding. After several vicissitudes related to the transfer of the Technological Polo to the Erzelli hill, Nuovo Borgo Terminal Containers opens its new headquarters in an area of about 25.000 square meters, beside the Genoa Voltri Port, near the Vte cranes. In 2019 Nuovo Borgo Terminal Containers Srl makes a very important choice, close NBTC Porto and open a new area near NBTC Voltri, the name will be NBTC Mare. After the restoration works , this area will have over 20000 mq for own clients,and with NBTC Voltri will be a valid response to the demand for services of containers logistic in the Genoese shipping view. NBTC has recently realized a co-financed plan in the ambit of the POR CRO of The Liguria District 2007-2013

A Well-equipped workshop for Dry e Reefers repairs

NBTC and Reefers NBTC repair reefer container units since many years, before with external collaborators and since January 2016 with own specialized technicians. Actually NBTC is Carrier and Daikin Dealer and it's a very important reference point in Genouese shipping.

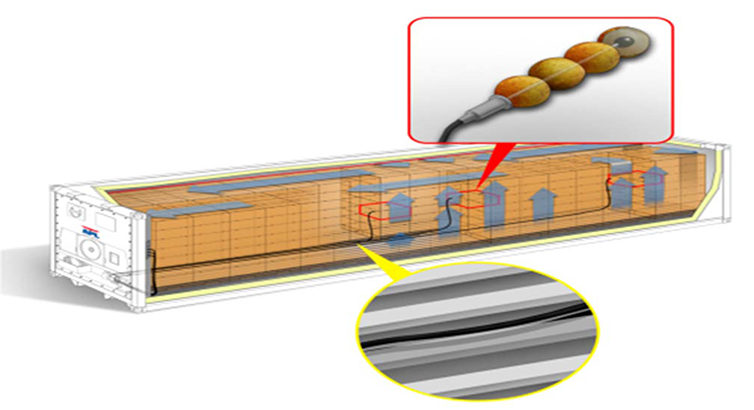

For the treatment to be effective, the fruit must be maintained at the temperature stipulated in the protocol of the individual country. Therefore, being able to control the temperature is vital. The exporter should pre-cool the fruit at the temperature indicated in the protocol for at least 48 hours before loading. The empty reefer container undergoes an inspection known as a pre-trip inspection in which: The refrigeration unit is checked to ensure that the temperature control and measuring and data recording equipment are functioning correctly. It is checked for structural damage. The cleanliness of the container is checked prior to goods being loaded. The container is prepared and set up with the temperature, humidity and ventilation requested by the supplier or loading company via email. The exporter checks the functioning and cleanliness of the reefer container. If it is not in perfect working order, temperature spikes could cause erroneous readings and the cold treatment process would have to be repeated. A plant health inspector from the Ministry of Agriculture goes to the client’s warehouse where loading takes place to ensure the three probes are correctly introduced into the fruit (a probe is an instrument which is introduced into a body or substance to explore a part of it or to extract or introduce substances). The probes record the temperature of the fruit at three particular points within the container which are specified in the individual protocol. Before being inserted, the probes are calibrated to ensure they function correctly. This is done by submerging the probes in ice until they reach 0ºC. They are left to warm up before being placed in the ice again several times to ensure that they are working perfectly. Once calibrated, and the fruit is loaded into the container, the probes are pushed into the fruit until they reach the flesh as the important thing is the temperature of the fruit and not of the container. In each cold treatment the three probes have to be below the required temperature. Once placed, the technicians record the fact that the probes are functioning correctly, they certify that the requirements are met and they attach this information to the phytosanitary certificate.

Specialized Technicians, by Shipowner, Port technicians or Ship agents requests, receive the assignment to repair fully units on Port.